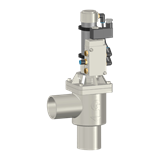

Angle Valve

Angle valves are used to shut off clean air exhaust pipes from separators, suction high-fillers, etc. and are available for pipe sizes 50, 65, 80 and 100 mm. The valve is operated by a double-acting pneumatic cylinder.

Our angle valves have a modular design and can be optionally equipped with solenoid valves and solenoid switches in standard design or EX-II-2D design.

The angle waves are fitted with clamp couplings.

-

Customer-oriented approach

-

Guaranteed quality

-

Fast delivery times

Advantages

- Simple mounting

- Light and compact construction

- Maintenance-friendly

- Simple and effective vacuum interruption technology

Angle valves are used to shut off clean air suction lines from separators, suction high-fillers, etc.

They are equipped with ventilation openings in the cover (figure 2).

Side A should be connected to the separator, suction high-filler etc. and side B to the vacuum pipe (Figure 3).

be connected to the vacuum line (vacuum unit).

The aeration openings are released as soon as the connection to the vacuum generator is closed (Figure 2).

The inflowing air flows in the direction of (e.g.) the separator (Figure 2) and ensures that the negative pressure in it is lifted.

As soon as the connection to the outside air is closed (figure 1), connection to the vacuum unit occurs and suction is applied.

Fastening of the angle valve is done by means of clamp couplings (e.g. Techno G type PC).

The angle valves can optionally be fitted with solenoid valves for 230 VAC or 24 VDC in both standard and Ex-II-2D versions.

Optionally, the double-acting pneumatic cylinder can be supplied with magnetic switches (reed contacts) for signalling the end positions.

The contactors are available in standard version or in Ex-II-3D version in 24 VDC with either an M12 plug or open end.

Angle valves may be mounted vertically or horizontally and, if necessary, upside down.

- Cast aluminium alloy body (01) with smooth connection stubs (AVP) or one-sided smooth connection stub and oval flange on the device side (AVF).

- Cast cover made of alloy aluminium (02), equipped with air inlet openings and a round flange section for mounting the compressed air cylinder.

- Valve made of alloy aluminium (03) which is flexibly mounted on the piston rod of the compressed-air cylinder.

- Sealing is by means of sealing rings fitted in the body and cover. The sealing ring in the body is glued with Loctite 454 (Gel) and the sealing rings in the cover are glued with Loctite 406.

- The valve is operated by a double-acting pneumatic cylinder (04) controlled by a solenoid (05).

- As an option, the pneumatic cylinder can be fitted with solenoid switches (06).

- In such a case, the magnetic switches (reed contacts) are supplied complete with fixing brackets (07). These mounting brackets can be clamped over the cylinder and pushed back and forth.

- Due to the integrated control cable (standard length 5 m) and the sensitivity of the magnetic switches, these are always supplied separately in the original packaging. The magnetic switch should be inserted into the carriage of the mounting bracket and set to the correct switching point using the adjusting screw "S".

Tubedimensions

| AV-50 | AV-65 | AV-080 | AV-100 | |

|

Tube connection in mm |

50 | 65 | 80 | 100 |